Introduction

Actuators are essential devices that convert different energy forms into mechanical motion for various applications. They are used in a wide range of industries, including robotics, aerospace, automotive, and manufacturing.

different types of actuators are designed to suit specific requirements, and each type has unique capabilities. In this article, we will explore ten different types of actuators in more detail and their applications.

Hydraulic Actuators

Hydraulic actuators convert fluid power into mechanical motion, which can be used to control motion, pressure, and force. They are ideal for applications that require high force, such as heavy-duty construction equipment, material handling, and agriculture machinery. Hydraulic actuators come in different types, including piston, diaphragm, and bellows.

Pneumatic Actuators

Pneumatic actuators use compressed air to create linear or rotary motion. They are simple, reliable, and cost-effective devices that require minimal maintenance. Pneumatic actuators are commonly used in the manufacturing industry, where they control the movement of valves, gates, and other automated equipment.

Electric Actuators

Electric actuators use electrical energy to control motion and force. They are highly precise and can be programmed to perform specific tasks, making them ideal for applications that require accuracy and repeatability. Electric actuators come in different types, including ball screw, roller screw, and linear motor.

Thermal Actuators

Thermal actuators use temperature changes to create motion. They are commonly used in HVAC systems, where they control the flow of refrigerant to regulate room temperature. Thermal actuators come in different types, including wax, bimetallic, and shape memory alloy.

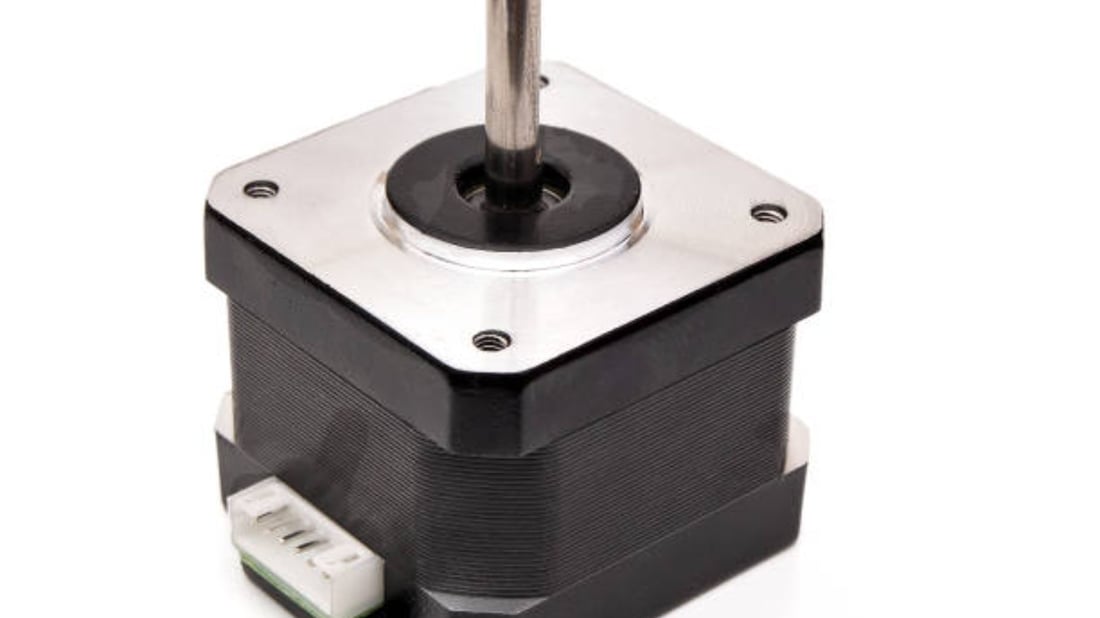

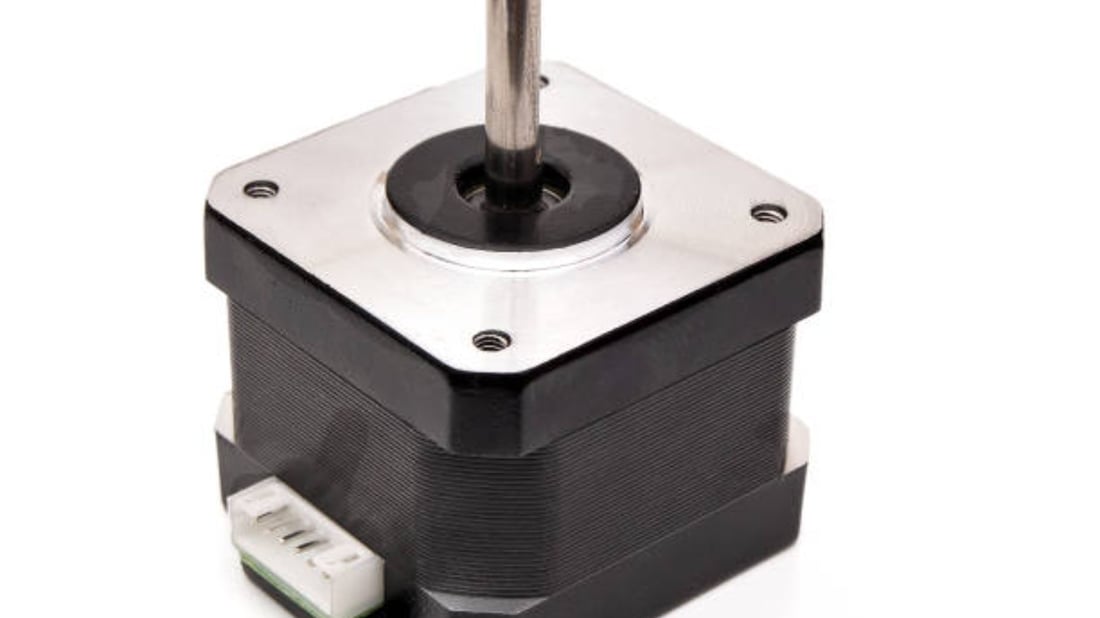

Electro-Mechanical Actuators

Electro-mechanical actuators use electrical energy to control mechanical motion. They are versatile devices that can be used for different applications, such as robotics, aerospace, and automotive systems. Electro-mechanical actuators come in different types, including linear and rotary actuators.

Solenoid Actuators

Solenoid actuators use electromagnetic forces to create motion. They are commonly used in applications that require fast response times, such as valves, locks, and latches. Solenoid actuators come in different types, including push, pull, and rotary.

Muscle Wire Actuators

Muscle wire actuators use shape memory alloys to create motion. They are ideal for applications that require lightweight, compact, and precise actuators, such as medical devices, micro-robots, and aerospace components. Muscle wire actuators come in different types, including Nitinol and copper-zinc-aluminum-nickel.

Hydrostatic Actuators

Hydrostatic actuators use liquid pressure to create motion. They are ideal for applications that require accurate, responsive, and high-force actuators, such as CNC machines, boring mills, and metal stamping presses. Hydrostatic actuators come in different types, including hydraulic and pneumatic.

Magnetic Actuators

Magnetic actuators use magnetic forces to create motion. They are ideal for applications that require low-cost, reliable, and easy-to-operate actuators, such as electromagnetic relays, switches, and motors. Magnetic actuators come in different types, including solenoid, voice coil, and linear stepper.

Flexure Actuators

Flexure actuators use flexible structures to create motion. They are ideal for applications that require precision, stability, and low cost, such as micro-positioning, Nano-imaging, and laser machining. Flexure actuators come in different types, including leaf springs, compliant mechanisms, and cantilever beams.

Conclusion

Different types of actuators are used in various applications to create motion, force, and pressure. Each type has unique capabilities and advantages that make it suitable for specific requirements. Choosing the right type of actuator is crucial for ensuring optimal performance and efficiency.

Quote Inquiry

Contact us!