Introduction

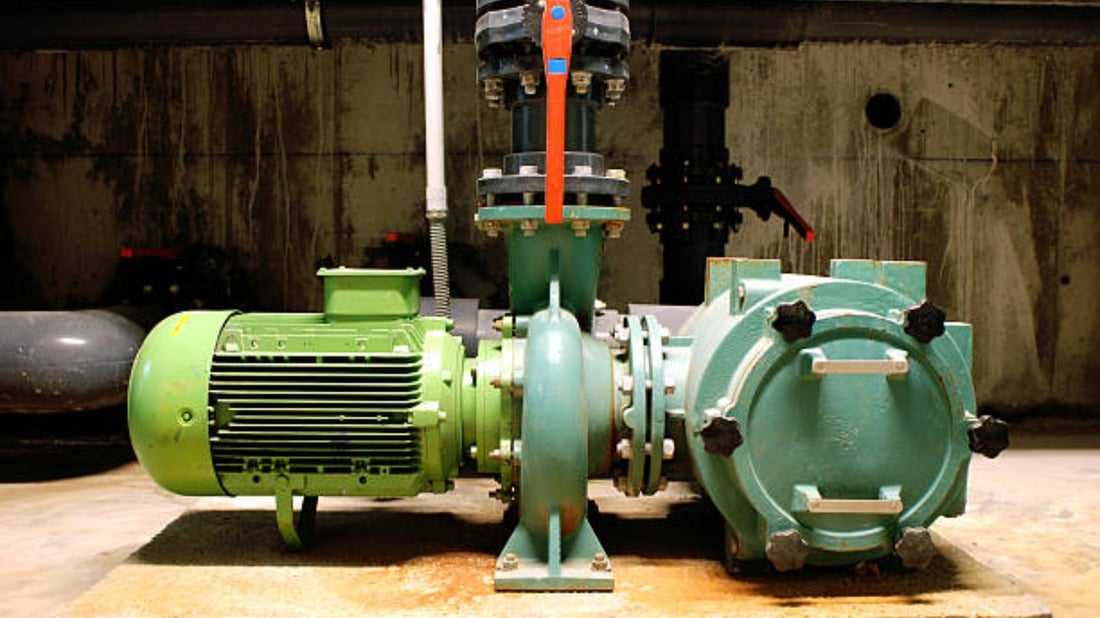

Industrial pumps are an essential tool in various industrial sectors. The gear pump type is a positive displacement pump that is widely used in industrial applications. It operates on the conveying principle, which means that it displaces a fixed amount of fluid per revolution. This article aims to provide you with a comprehensive guide on the gear pump type.

What is a Gear Pump Type?

The gear pump type is a type of positive displacement pump that is used to transfer different types of fluids. It has two meshed gears that rotate in opposite directions and generate a flow of fluid. The gears are usually made of materials like bronze, cast iron, or stainless steel. Gear pumps are best suited for low-to-medium viscosity fluids.

Working Principle of Gear Pump Type

The working principle of the gear pump type is relatively simple. The pump consists of two gears that have precisely cut teeth. As the gears rotate, they move the fluid from the inlet side of the pump to the outlet side. The liquid is displaced in the gaps between the teeth of the gears and the casing walls. The design of the gear pump type ensures that there is no pulsation in the flow of fluid.

Advantages of Gear Pump Type

The gear pump type has several advantages over other types of pumps. Some of these advantages include:

- Efficient and reliable

- Low maintenance

- Can handle a wide range of fluids

- No need for valves or complex controls

Disadvantages of Gear Pump Type

The gear pump type also has some disadvantages that you need to consider. These disadvantages include:

- Not suitable for high-pressure applications

- Requires a well-lubricated fluid

- Limited to low-to-medium viscosity fluids

Applications of Gear Pump Type

The gear pump type is used in various industrial applications. Some of the most common applications include:

- Chemical processing

- Food and beverage processing

- Pharmaceuticals

- Oil and gas refining

- Agriculture

- Paint and coatings

Types of Gear Pump

There are three main types of gear pumps:

- External gear pump

- Internal gear pump

- Gerotor pump

External Gear Pump

The external gear pump is the most common type of gear pump. It has two gears, one with external teeth and one with internal teeth. The fluid enters the pump between the teeth of the gears and the casing walls and is carried around to the discharge side.

Internal Gear Pump

The internal gear pump has an internal rotor with external teeth and an external rotor with internal teeth. The fluid enters the pump through the inlet and moves along the inside of the external rotor. The fluid is then trapped between the teeth of the two rotors and carried around to the discharge side.

Gerotor Pump

The gerotor pump has an internal rotor with external teeth and an outer stator with internal teeth. The fluid enters the pump and moves along the inside of the outer stator. The fluid is then trapped between the teeth of the rotor and the stator and carried around to the discharge side.

Conclusion

The gear pump type is a popular and reliable positive displacement pump that is used in various industrial applications. Its simple design, low maintenance, and ability to handle a range of fluids make it an excellent choice for many industrial sectors.