Electromechanical actuators are devices that convert electrical energy into mechanical motion. They are commonly used in various industries for precision motion control applications. These actuators offer high levels of accuracy, repeatability, and efficiency compared to other types of actuators.

Types of Electromechanical Actuators

There are several types of electromechanical actuators, including linear actuators, rotary actuators, and lead screw actuators. Linear actuators are used for creating linear motion, while rotary actuators are used for creating rotary motion. Lead screw actuators utilize a threaded screw to convert rotational motion into linear motion.

Applications of Electromechanical Actuators

Electromechanical actuators are widely used in various industries, such as aerospace, automotive, robotics, and industrial automation. They are commonly used in applications that require precise positioning, such as robotics arms, medical devices, and precision manufacturing equipment.

Advantages of Electromechanical Actuators

One of the main advantages of electromechanical actuators is their high level of precision. They offer accurate positioning and control, making them ideal for applications that require precise motion. Electromechanical actuators also offer high levels of efficiency, reliability, and repeatability.

Disadvantages of Electromechanical Actuators

Despite their many advantages, electromechanical actuators also have some disadvantages. They can be more expensive than other types of actuators, such as hydraulic or pneumatic actuators. Electromechanical actuators also require electrical power to operate, which can be a limitation in certain applications.

Selection Considerations for Electromechanical Actuators

When selecting an electromechanical actuator for a specific application, there are several factors to consider. These include load capacity, speed, accuracy, duty cycle, environmental conditions, and control interface. It is important to carefully evaluate these factors to ensure the chosen actuator meets the requirements of the application.

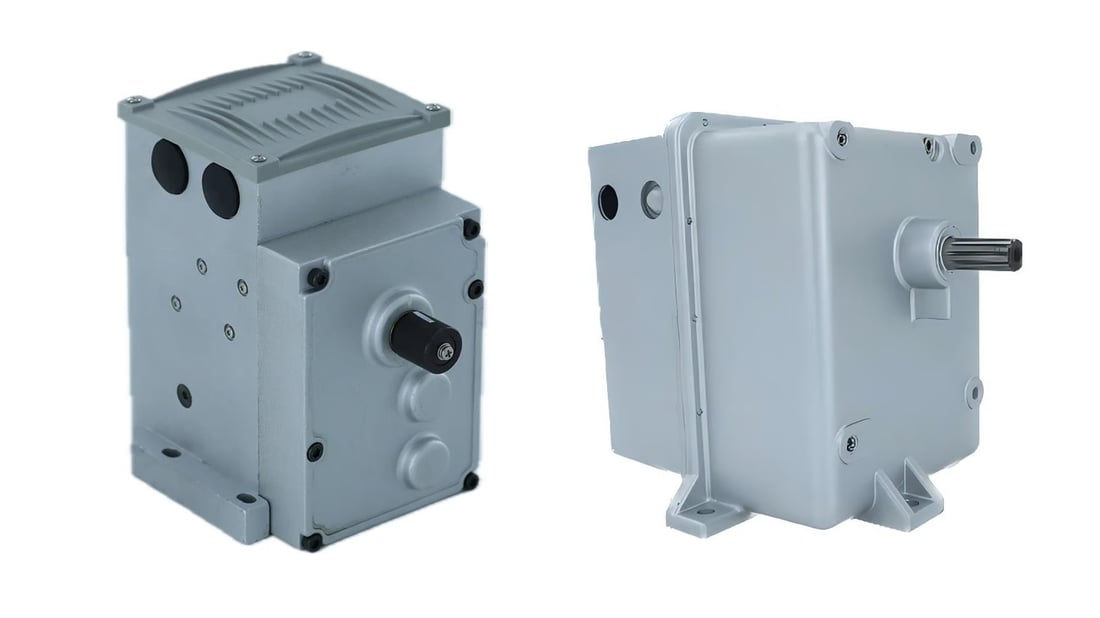

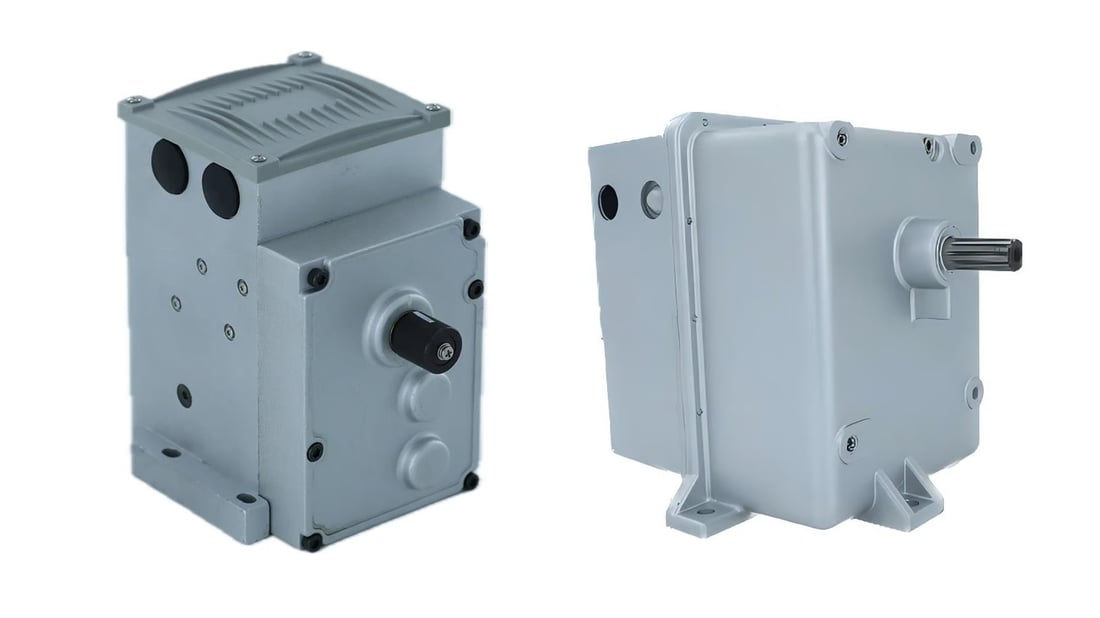

Key Components of Electromechanical Actuators

Electromechanical actuators consist of several key components, including a motor, gearbox, lead screw or ball screw, and control electronics. The motor is responsible for converting electrical energy into mechanical motion, while the gearbox helps to increase torque and reduce speed. The lead screw or ball screw converts rotational motion into linear motion.

Future Trends in Electromechanical Actuators

With advancements in technology, electromechanical actuators are becoming more compact, lightweight, and energy-efficient. There is a growing trend towards the development of smart actuators that integrate sensors and feedback control systems for improved performance and accuracy.

Environmental Impact of Electromechanical Actuators

Electromechanical actuators are more environmentally friendly than hydraulic or pneumatic actuators, as they do not require fluids for operation. They also have lower energy consumption and reduced maintenance requirements, making them a sustainable choice for various applications.

Conclusion

In conclusion, electromechanical actuators play a crucial role in various industries that require precise motion control. They offer high levels of precision, efficiency, and reliability, making them ideal for applications where accuracy is paramount. With ongoing advancements in technology, electromechanical actuators are expected to continue evolving and improving in the future.

Quote Inquiry

contact us