Introduction

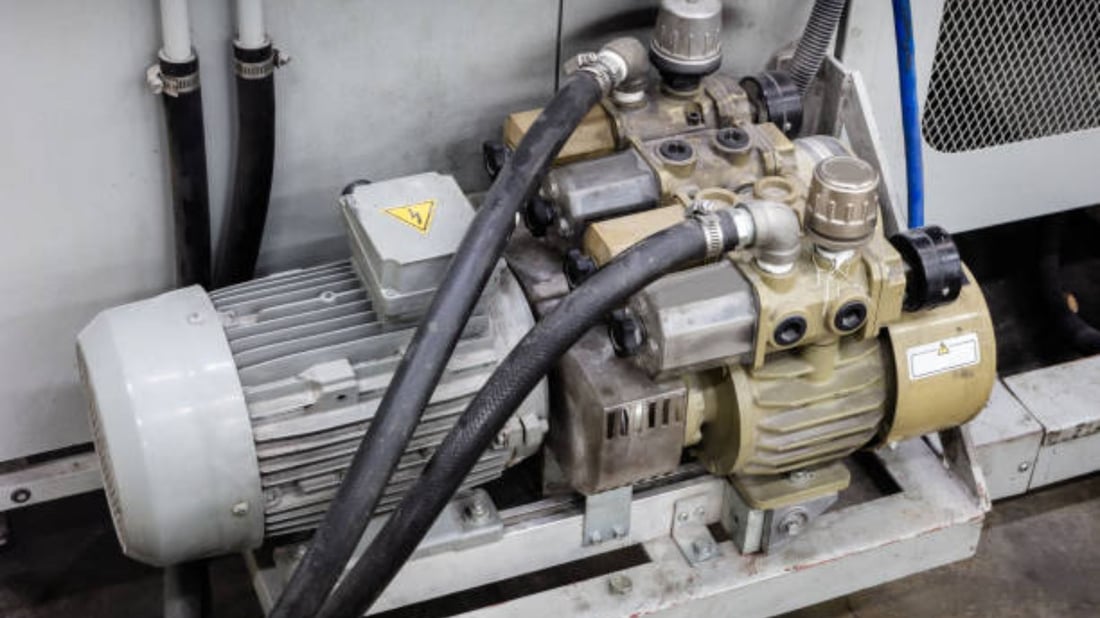

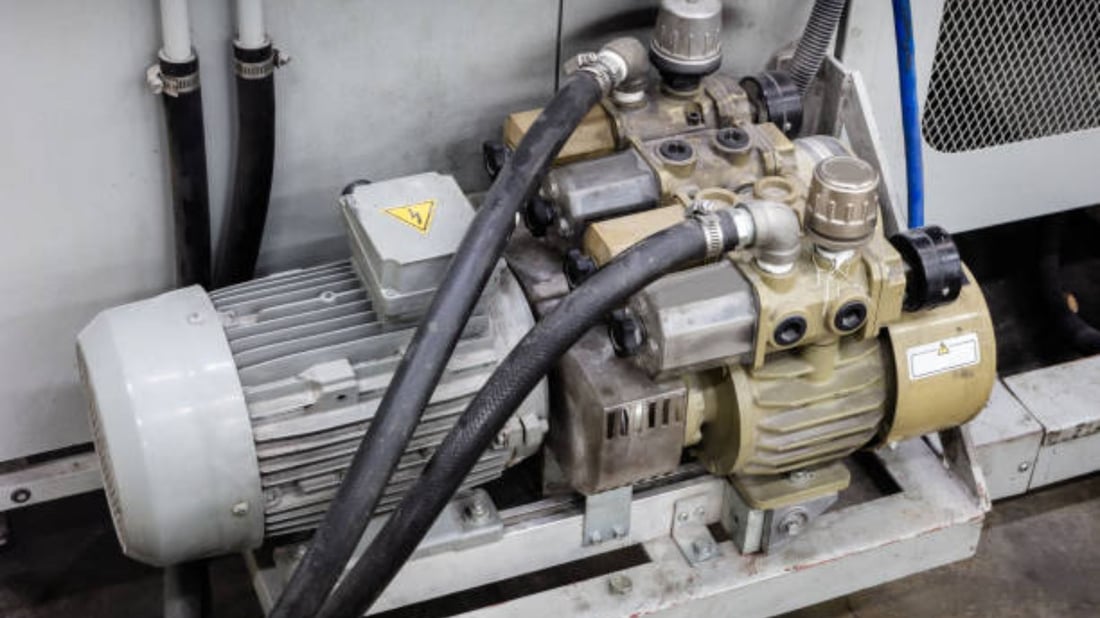

Oil pumps in compressors are essential to prevent friction between moving parts, ensuring their longevity and peak efficiency. In industrial applications, compressors are highly relied upon to boost the pressure of air, gas, or steam. Every compressor requires a lubrication system that includes a pump to circulate oil throughout the system. The location of oil pumps on a compressor can vary depending on the type, size, and design. In this article, we will explore where oil pumps are typically located on a compressor and why.

Inside the Compressor

The oil pump in compressors is generally located inside the compressor itself. The pump draws oil from the reservoir, and then it is distributed to all the moving parts that require lubrication. Compressors that operate on a rotary or centrifugal design typically have oil pumps integrated within the compressor housing. In contrast, reciprocating compressors often have a separate oil pump that is installed outside the compressor.

Reciprocating Compressors

Reciprocating compressors are the most common type of compressor used in industrial applications. The oil pump for reciprocating compressors is typically located outside the compressor housing and connected to the oil reservoir by a suction pipe. The pump delivers the oil through a pressure line to the compressor cylinder, where it is distributed to lubricate all the moving parts. A separate oil filter may also be installed outside the compressor to ensure the oil stays clean.

Rotary Screw Compressors

Rotary screw compressors are known for their high efficiency, low noise, and low maintenance requirements. The oil pump in rotary screw compressors is usually integrated into the compressor unit, located within the compressor housing. The pump draws oil from the reservoir and distributes it to the rotors and bearings to keep them lubricated. The oil is also used to cool the compressor components during operation.

Centrifugal Compressors

Centrifugal compressors are used for high-volume applications and are known for their energy efficiency. The oil pump for centrifugal compressors is typically located inside the compressor housing, integrated into the compressor unit. The pump delivers a constant stream of oil to the bearings of the compressor's impeller, keeping them lubricated and cool. Unlike reciprocating compressors, centrifugal compressors do not require an oil filter.

The Importance of Oil Pumps

Oil pumps play a critical role in maintaining the performance and longevity of compressors. Without proper lubrication, moving parts can seize, produce excessive heat, and even lead to catastrophic failure. Oil pumps ensure that lubricating oil is distributed to all the necessary parts, providing protection from friction and wear. They also help to remove heat generated during the compression process, prolonging the lifespan of the compressor.

Maintenance and Troubleshooting

Regular maintenance of oil pumps and lubrication systems is essential for longevity and reliability. Oil filters must be changed regularly to maintain oil quality and prevent debris from entering the pump. Oil levels should also be routinely checked to ensure proper lubrication of all parts. If there are any issues with oil circulation, such as low oil pressure, unusual noise, or overheating of components, it is essential to troubleshoot and rectify the issue immediately.

Conclusion

Oil pumps are an integral component of compressor systems, providing necessary lubrication and protection to moving parts. The location of the oil pump depends on the type, size, and design of the compressor. In reciprocating compressors, the oil pump is often located outside the housing, whereas in rotary and centrifugal compressors, the pump is usually integrated within the compressor unit. Regular maintenance and troubleshooting of the lubrication system are vital to ensuring the longevity and reliable operation of the compressor.

Quote Inquiry

Contact us!