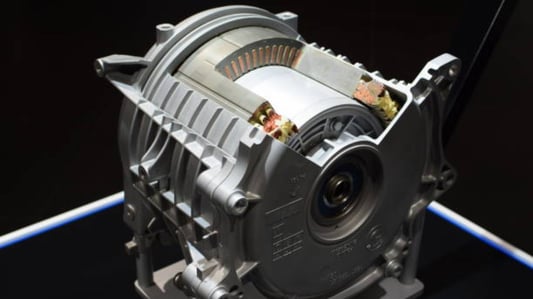

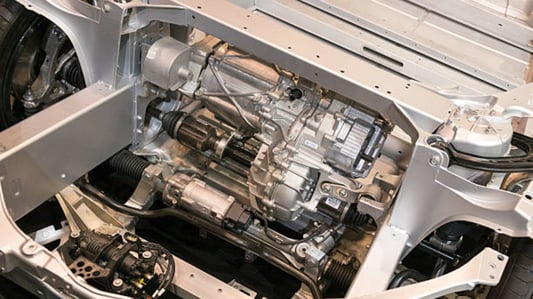

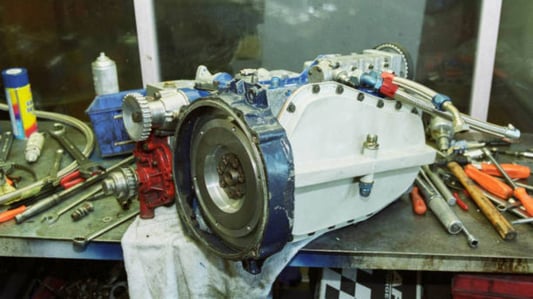

What is a pressure gear pump? A pressure gear pump is a type of positive displacement pump that uses rotating gears to pressurize fluid and transfer it from the inlet to the outlet. These pumps are commonly used in various industrial applications to move high-viscosity fluids at high pressure levels. How Does a Pressure Gear Pump Work? Pressure gear pumps work by trapping fluid between the gear teeth and the casing of the pump, creating a seal that pushes the fluid from the inlet to the outlet. As the gears rotate, the fluid is pressurized and forced out of the pump. Advantages of Pressure Gear Pumps Pressure gear pumps offer several advantages, including compact size, high efficiency, and the ability to handle high pressures and viscous fluids. They are also relatively low cost compared to other types of pumps. Applications of Pressure Gear Pumps Pressure gear pumps are commonly used in hydraulic systems, lubrication systems, fuel transfer systems, and various industrial processes where high pressure and high viscosity fluids need to be moved efficiently. Types of Pressure Gear Pumps There are two main types of pressure gear pumps: external gear pumps and internal gear pumps. External gear pumps have two gears that mesh externally, while internal gear pumps have one gear inside another gear. Benefits of External Gear Pumps External gear pumps are known for their simplicity, efficiency, and reliability. They are commonly used in applications where a compact and cost-effective solution is required for high-pressure fluid transfer. Benefits of Internal Gear Pumps Internal gear pumps are known for their ability to handle high viscosity fluids and provide smooth, pulse-free flow. They are ideal for applications that require precise fluid metering and control. Maintenance of Pressure Gear Pumps Proper maintenance is essential to ensure the long-term performance and durability of pressure gear pumps. Regular inspections, lubrication, and replacement of worn parts are necessary to prevent breakdowns and ensure optimal pump efficiency. Choosing the Right Pressure Gear Pump When selecting a pressure gear pump for your application, consider factors such as flow rate, pressure rating, viscosity of the fluid, and compatibility with the operating conditions. Consulting with a pump specialist can help you make the best choice. Conclusion Pressure gear pumps are versatile and reliable devices that play a crucial role in various industrial processes. Understanding how these pumps work and their unique benefits can help you make informed decisions when selecting a pump for your specific needs.Quote InquiryContact us!